By Chloë Noonan

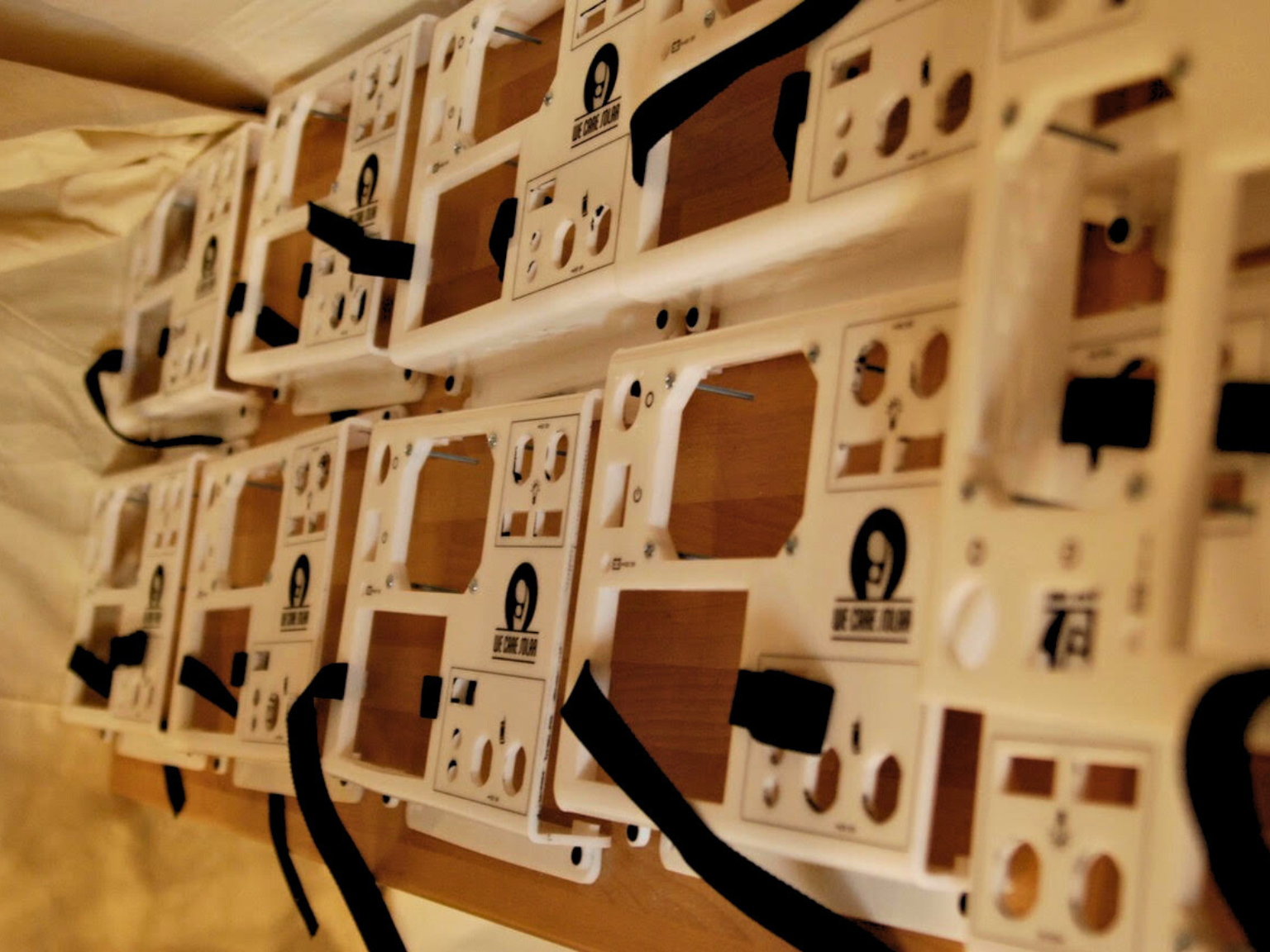

In the early years of We Care Solar, every Solar Suitcase was built by hand—one at a time, often by students, volunteers, and our own team—for a health facility in need of light for safe deliveries.

“Brent Moellenberg and I were the first factory,” recalled co-founder Hal Aronson. “We were soldering wires on kitchen tables and figuring things out one unit at a time.”

Each suitcase was a one-of-a-kind creation, carefully assembled in homes, garages, backyards, and borrowed workspaces. “I mean, I had my kids cutting wires,” said Brent. “It was a mess of everything.”

Most often, the suitcases were personally delivered to their destination by Dr. Laura Stachel or a volunteer courier.

In 2010, co-founders Laura Stachel, Brent Moellenberg, and Hal Aronson were tasked with producing 20 Solar Suitcases for clinics in Liberia at the request of the World Health Organization. It was the largest order they had ever received; every unit had to be identical, yet assembled by hand. To meet the challenge, Brent, volunteering full-time, set up at TechShop in San Francisco.

“I remember cutting the chassis out of plastic sheets with a laser cutter,” Brent said. “We were hand-building everything—lights, wiring harnesses, even making our own tools to bend and form the chassis.”

This hands-on process was full of heart, but it couldn’t meet the growing demand from clinics across Africa and Asia. “We had this moment of, ‘This is amazing, but also unsustainable,” reflects Brent. The demand for safe, reliable light in health clinics far outpaced what we could do with volunteer builds and late-night wiring sessions.

The First Production Line

To move forward, We Care Solar partnered with Morgan Royce Industries (MRI), a small contract manufacturer in Fremont, California, led by the late Larry Johnston.

“Larry didn’t just offer us floor space,” said Hal. “He offered us mentorship, care, and a team who believed in our mission.” Hal said. “It felt a lot like family.”

With MRI, and the support of the MacArthur Foundation, the first production line for the Solar Suitcase was born. Every component was built to specification, tested for safety, and assembled with precision.

“What we used to do with a screwdriver and wire cutters became documents, torque specs, burn tests, and circuit boards,” Brent said.

We worked with Everbright Solar to commission lightweight solar panels that could fit inside the lid of the suitcase itself.

One of the hardest components to get right was the medical procedure light.

“We had a bunch of failures,” Brent admitted. “Lights that overheated, flickered, or didn’t render skin tone accurately. After searching exhaustively for an off-the-shelf lighting solution, we eventually realized: We can’t just buy a light. We have to build one.”

We Care Solar worked with volunteer engineer David Miller to create a custom LED light specifically designed for clinical care—low-power, high-efficiency, and high color rendering.

“We even had to get creative in testing how well the light rendered colors in a clinical setting,” Hal said.

“The lights we send today are based upon David Miller’s original circuitry,” Brent said. “It continues to be a fantastic design.

A Shipment Like No Other

By 2012, We Care Solar celebrated its first shipment of fully assembled Solar Suitcases.

“That was the first time we had a complete suitcase made where we had not had to actually make anything ourselves,” Brent recounted.

From 20 hand-built units to global deployment, this shift marked a turning point. It allowed us to deliver consistent, high-quality systems—ready to light births in clinics around the world.

Why It Matters

This wasn’t just about production—it was about trust. Every circuit, every light, every fixture was built for the realities of off-grid maternal care and the health workers who depend on light to save lives. And it was this turning point that enabled us to grow from a small operation to a global solution.

Today, more than 10,000 health facilities have been equipped with Solar Suitcases, and over 44,000 health workers have been trained to use them.

It all began with a team that refused to settle for “good enough.”

Gratitude to Our Builders

This breakthrough was only possible thanks to the brilliance and dedication of many:

Brent Moellenberg, Charles Liu (Everbright Solar), David Miller, Hal Aronson, Laura Stachel, Holly Solar, Tom Nelson (West Coast Fab), Mo Ahady (Digicom) and the late Larry Johnston and his team at Morgan Royce Industries—along with the volunteers, students, and factory workers who helped build those early units by hand.

And today, we extend deep gratitude to our current manufacturing partners, Arrow Electronics and Premier Manufacturing, whose commitment and expertise help us produce high-quality Solar Suitcases at scale—upholding the standards we established from the very beginning.